Tianqiong Sensor IOT Technology Co., Ltd

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

Model:FT-EC08

Brand:tianqiong

1.Introduction to Odor gas detector product functions

Odor gas detector can detect toxic and harmful gases online 24 hours a day and can qualitatively measure the concentration of odorous gases.

1.The monitoring equipment can simultaneously monitor composite odor gas (OU), volatile organic gas (TVOC), hydrogen sulfide, ammonia, and meteorological parameters (temperature, humidity).

2.The monitoring equipment has good anti-interference ability and has the function of self-recovering of power outage calls.It has waterproof and dustproof design and supports GPRS wireless communication.

3.Monitoring equipment must comply with the "Standard for Online Monitoring (Monitoring) System Data Transmission Standards" HJ212-2017.

4.The monitoring equipment has an alarm function and adopts an integrated design, which can realize the light alarm function of exceeding the standard of local monitoring factors.

5.The monitoring equipment has local and remote calibration functions, and has a pre-treatment system (dust removal, water vapor and other impurities) with one-click silence.

6.The main interface of the monitoring device displays a real-time curve for nearly 60 seconds, and the concentration values are displayed in numbers and graphs.

7.The monitoring equipment can adopt vertical pole and wall-mounted installation methods.

8.Life cycle management system, the system manages life of the main components and can provide alarm prompts based on the remaining life set;

9.The device needs to be equipped with a color touch screen for easy debugging operation;

10.The device has the function of expanding GPS positioning, and the monitoring data can be stored in association with GPS positioning information;

11.Has high-performance industrial-grade wireless module; has high-performance industrial-grade 16/32-bit communication processor; has a complete anti-disassembly mechanism to ensure that the data terminal is always online; RS232/RS485 interface.

12.Signal output: 4G wireless transmission function, RS-485

13.Working power supply: AC220V±10%, 50HZ, 5A

14.Operating temperature: -30~70℃ (referring to the processor part)

15.Working humidity: 0~90%RH

16.Built-in 4G wireless communication module, which can set and modify the wireless transmission data transmission interval, sending IP/domain name address, and supports the HJ212 protocol.Seamlessly connect with customers and the Environmental Protection Bureau platform, last time "real-time", "minutes", "hours", and "days".

2.Odor gas detector product technical parameters

| Odor gas detector technical parameters | |||||||

| Place of origin | China | brand | Fengtu Technology | model | FT-EC08 | ||

| Serial number | Configuration name | unit | quantity | parameter | |||

| 1 | Host | tower | 1 | Test items: ammonia, hydrogen sulfide, odor concentration, methylmercaptan, trimethylamine, carbon disulfide, methylsulfide, dimethyldisulfide, styrene.(Select monitoring factor according to customer needs) | |||

| 1.1 | Including electrochemistry, PID photoion, and metal MOS sensors; | set | 1 |

⑴.Electrochemical sensors are respectively tested accordingly: Regular four parameters: Ammonia: (0-10)ppm; Hydrogen sulfide: (0-20)ppm; TVOC: (0~20)ppm; Odor: (0~1000)OU Standard eight parameters: Ammonia: (0-10)ppm; Hydrogen sulfide: (0-20)ppm; Methylmercaptan: (0-20)ppm; Methylsulfide: (0-20)ppm; Dimethyl disulfide: (0~20)ppm; Carbon disulfide: (0~20)ppm; Styrene: (0-10)ppm; Trimethylamine: (0-10)ppm; ⑵.Error: FS.≤±5% ⑶.Ambient temperature: -20℃-+50℃. ⑷.Ambient humidity: 0-95%RH. (Select monitoring factor according to customer needs) |

|||

| 1.2 | Injection control pump system | set | 1 | (1) Injection flow: 400-600 ml/min, built-in sampling system.(2) Built-in sampling system: built-in brushless air pump sampling | |||

| 1.3 | Filter | set | 1 | Small hydrophobic device (filters trace dust and water vapor in the atmosphere) | |||

| 1.4 | Other accessories | set | 1 | Connecting pipe fittings, etc. | |||

| 2 | Data transmission system | tower | 1 | (1) Dimensions: 91*58*22mm; (2) Equipment weight: 300g; (3) Support TD-SCDMA, WCDMA, EVDO, CDMA, GPRS | |||

| 3 | Rainproof box | tower | 1 | Size: 410*272*540mm, material: cold rolled plate, surface sprayed white | |||

| 4 | Pole | set | 1 | Size: 1200mm, material: galvanized pipe, surface sprayed white | |||

| 5 | Display | set | 1 | Built-in 5-inch touch screen, gas concentration values are displayed using digital and graphic | |||

3.Odor gas detector product features

Application environment

Sewage treatment plant

Rebuilding tobacco leaf factory

Landfill

Garbage transfer station

Chemical and industrial parks

4.Product installation

Fengtu Technology's odor gas monitoring system product construction and installation plan

HJ 664-2013 Technical Specifications for the Layout of Environmental Air Quality Monitoring Points (Trial)

1.Installation environment

The installation environment should comply with the operating environment (including ambient temperature, ambient humidity, and ambient pressure) requirements of the circulation environment monitoring system as much as possible.Areas with mechanical vibration, strong electromagnetic radiation, excessively fast air (wind speed) flow, and excessive ambient temperature and environmental humidity should be avoided as much as possible.If the air flow rate is too fast, it will affect the response time and detection results of the detection, and excessive ambient temperature and humidity will affect the detection results and the service life of the sensor.

2.Installation location

The overall principle should take into account factors such as the monitored gas diffusion space, wind direction, ambient temperature, ambient humidity, monitoring area enclosure, process pressure and distribution of surrounding equipment.Areas where people are on duty or are often stranded should be given priority.

Guide installation

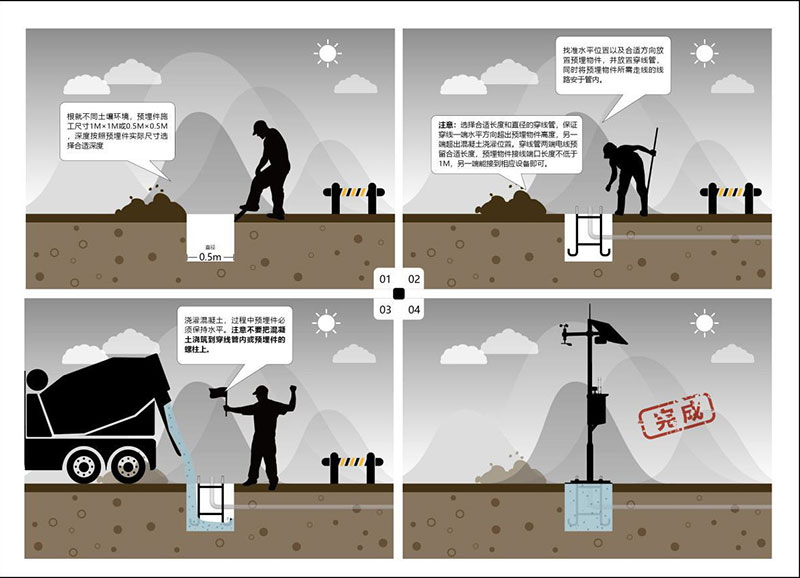

1.Construction of foundation pre-embedded and embedded parts

1.The middle frame of the ground cage is 21cm*21cm square, 51cm high, and the distance between the hook and hook on the outer bottom is 31cm, as shown in Figure 1.The pre-embedded construction size shall not be less than 50cm*50cm, and the depth shall be 40-43cm.

Figure 1

2.Find the horizontal position and place the embedded parts in the appropriate direction, with one front direction facing south.When pouring embedded parts, be careful not to pour concrete into the threading pipe or on the embedded parts studs.The embedded parts should be positioned in the soil pit, not be tilted, and the embedded parts should be fixed to prevent the position of the embedded parts from changing when pouring concrete.As shown in Figure 2.

3.Wiring, cabling reasonably in advance according to order needs, including power cords.If wiring is required, before pouring concrete, you need to place a threading pipe.The conventional plastic pipe made of PVC material has a diameter of custom-defined according to the size of the power supply cable.The threading pipe must be 5cm higher than the reserved hole in the center of the embedded part, and the other end can be connected to the corresponding equipment as the standard.

Figure 2

When traditional mechanical weather stations monitor wind speed and direction, they encounter a difficult problem. The wind speed sensor usually consists of wind cups and an axis, and the wind direction sensor relies on mechanical components such as a wind vane. When these mechanical components are...

China has a vast territory with complex and diverse geographical environments and significant differences in climatic conditions. As a crucial link for power transmission, transmission lines inevitably traverse special geographical areas such as valleys, high - altitude peaks, and rivers. These spec...

Under harsh low - temperature and freezing conditions, anemometers and wind vanes are highly prone to malfunction. As a result, the errors in the collected data increase significantly. Although these devices are equipped with heating units, the units only function on the rotating parts. Once severel...

Two - dimensional ultrasonic anemometers can only measure two parameters: wind speed and direction on the horizontal plane. They cannot obtain information about the wind in the vertical direction, such as vertical wind speed or the upward/downward speed of vertical airflows. Therefore, they are only...