Tianqiong Sensor IOT Technology Co., Ltd

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

time:2025-03-26 10:06:14 source:Weather Station viewed:2 time

Under harsh low - temperature and freezing conditions, anemometers and wind vanes are highly prone to malfunction. As a result, the errors in the collected data increase significantly. Although these devices are equipped with heating units, the units only function on the rotating parts. Once severely frozen, parts such as the wind cups and tail rudders still ice up. This leads to an increase in rotational inertia, causing substantial deviations in the data. Such data deviations can disrupt the control strategies of wind turbines, posing threats to the power output and operational safety of the turbines.

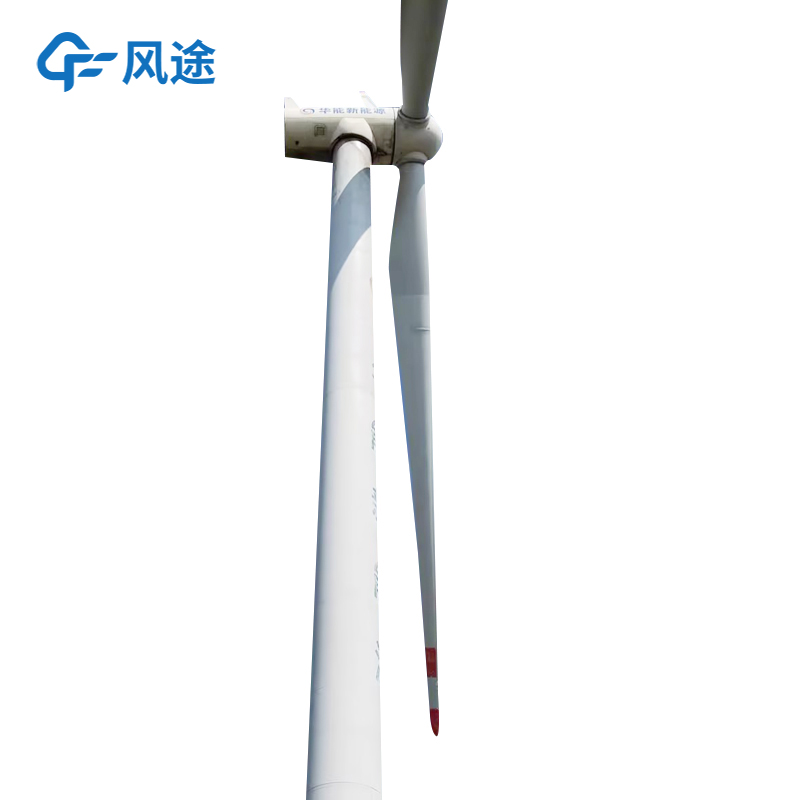

When ice accumulates on wind turbine blades, the load borne by the blades rises. This not only shortens the service life of the blades but also, due to the uneven distribution of ice loads on each blade, causes a sharp increase in the unbalanced load of the turbine. If the turbine continues to operate in this state, it is highly likely to be damaged. In severe icing conditions, the turbine has to be disconnected from the grid and shut down, greatly reducing the utilization rate of turbines in low - temperature regions.

Ice accretion on the blades alters the original airfoil shape and affects the load distribution. Clear ice, in particular, has a more severe impact on the aerodynamic performance of the blades. It can cause a significant decrease in the lift force of the blades and a reduction in the lift - to - drag ratio, with a maximum reduction of 61%. The airfoil also enters the stall state prematurely, deteriorating the aerodynamic performance. When the temperature rises, the falling ice poses a threat to the safety of equipment and on - site personnel. Therefore, it is extremely necessary to establish an effective Wind power icing thickness monitoring system.

The Wind power icing thickness monitoring system mainly consists of ice - detection sensors, a control PLC, and a de - icing subsystem. The ice - detection sensors are installed on the top of the nacelle. They can convert the detected ice - thickness information into voltage or current signals and then transmit them to the PLC of the main control system of the wind turbine. The PLC precisely controls the start and stop of the de - icing device based on the preset ice - layer thickness thresholds. By using the IO interfaces reserved in the PLC of the main control system of the turbine, it is possible to collect ice - thickness data and control the de - icing device, effectively reducing costs.

The installation of the Wind power icing thickness monitoring system does not require power outages. By combining unique microwave detection technology with temperature analysis, it can monitor the icing conditions of various towers, insulators, and transmission lines in real - time. The sensors of this device monitor the icing information in sensitive areas based on the differences in the feedback signals of microwave signals to different substances, calculate the ice - thickness, and can set alarm values to activate the de - icing system. The host processes the icing signals through sampling, filtering, etc. Using proprietary algorithms, it calculates the ice - formation rate and thickness. When the preset thresholds are reached, it sends alarms to the background via the 4G network to ensure the safety of the lines.

This device can conduct real - time online monitoring of icing and ice - cover thickness in the tower area, along with various meteorological parameters. It automatically stores and uploads data, analyzes icing conditions, and issues alarm prompts.

In the photovoltaic field, "black heart" is a serious quality issue, manifested as the luminous intensity of some areas inside the photovoltaic module being significantly lower than the normal level, presenting black or dark areas. This indicates that the performance of the battery cells i...

Wheat seedling conditions are usually classified into strong seedlings, robust seedlings (including first - class and second - class seedlings), and weak seedlings (third - class seedlings). For different seedling conditions, differential management measures need to be taken during key growth stages...

Agricultural production is closely related to weather changes, and weather conditions play a decisive role in the growth, development, and final yield of crops. Torrential rains may trigger floods, submerge farmland, and damage crops. Droughts, on the other hand, can lead to insufficient soil moistu...

The Portable el detector is an important device used to detect various defects in photovoltaic (PV) cell modules. It can accurately detect defects such as hidden cracks, fragments, and poor soldering in PV cell modules. These internal defects can seriously affect the service life and long-term power...