Tianqiong Sensor IOT Technology Co., Ltd

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

Model:FT-QL1

Brand:tianqiong

1.Bridge monitoring background

Bridge Monitoring provides complete structural health monitoring solutions for bridges and structures, ensuring the structural health and integrity of bridge infrastructure and components.As an important part of transportation, bridges have become more and more concerned with the development of my country's transportation industry.my country is a bridge power.According to the latest statistics from the Ministry of Transport, as of the end of 2019, there were about 878,300 highway bridges (excluding municipal bridges).Most factors affecting bridges are human factors, long-term overload of vehicles, material degradation, natural disasters, etc., resulting in various diseases such as reduced bearing capacity and structural damage in active bridges, and at the same time, lack of timely and in place management and maintenance.If the damage cannot be tested and repaired in time, it will affect driving safety and shorten the service life of the bridge, and in severe cases, it will lead to sudden damage and collapse of the bridge.Therefore, it is particularly urgent to establish an intelligent online monitoring system for bridges and promptly detect damage to the bridge structure.

2.Overview of Bridge monitoring system

Our company has many years of experience in bridge monitoring and has established an intelligent, informative and automated online bridge monitoring system.It can fully grasp the safety status of bridge construction and operation, and play a huge role in bridge construction, daily maintenance, management and emergency response to emergencies.Based on the cloud computing service center, it can accommodate all bridge monitoring systems in the area, form a regional bridge health monitoring platform, and realize unified monitoring and management of all bridge structures in the area.

3.Main monitoring contents of Bridge monitoring

1.Geometric linear monitoring: arch rib linear monitoring, main beam deflection monitoring, axis offset measurement;

2.Stress and strain monitoring: beam body strain, bridge tower strain, main arch strain, bridge pier strain, etc.;

3.Cable force/tension monitoring: tie rod tension, suspender boom tension, anchor cable stress, etc.;

4.Environmental monitoring: wind speed, wind direction, temperature and humidity, rainfall, visibility, corrosion

7.Position monitoring: tower top deviation, arch foot deviation, and arch top deviation;

8.Vibration monitoring: beam body vibration, arch top vibration, bridge tower vibration, boom (cord) vibration;

9.Load monitoring: dynamic weighing system;

10.Inclination monitoring: bridge tower incline, bridge pier incline, beam body incline;

11.Other monitoring: crack monitoring, fatigue monitoring, ship collision, camera.

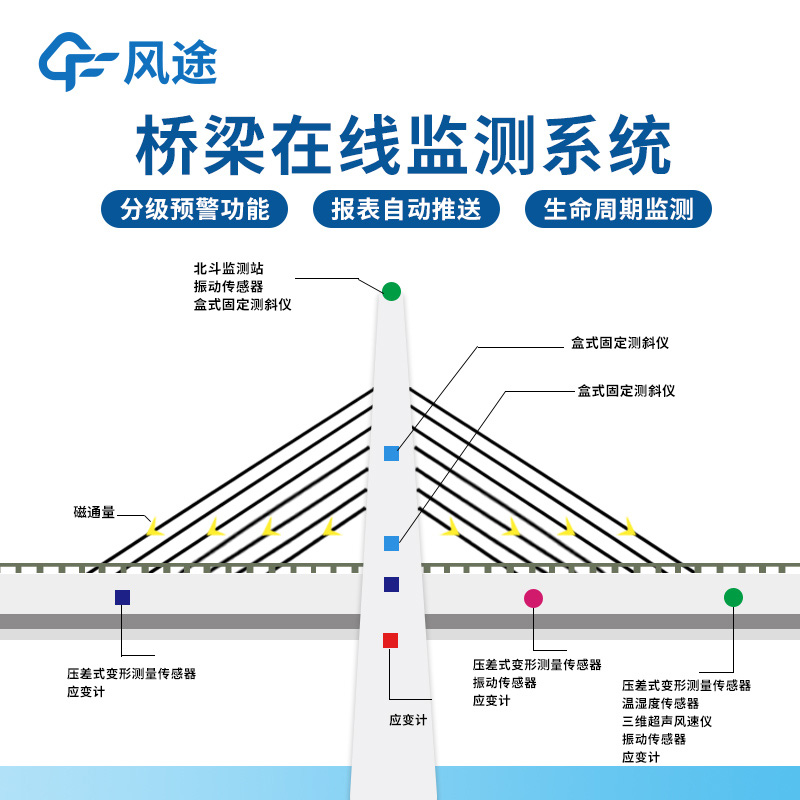

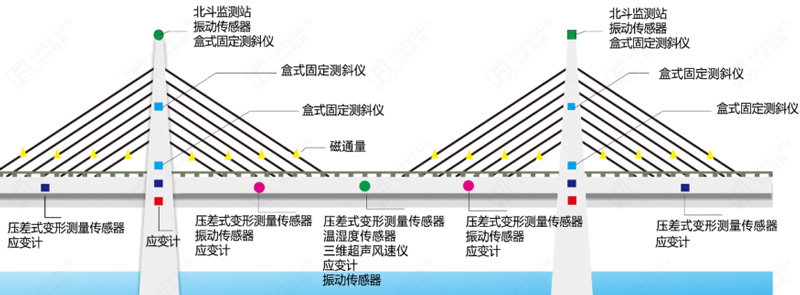

4.Bridge monitoring diagram

5.Bridge monitoring monitoring project list

| Monitoring items | Device name | Monitoring items | Device name |

| Stress and strain | Strain gauge | Explosive joints | Linear displacement sensor |

| Soli | Magnetic flux sensor/accelerometer/anchor cable meter | Temperature and humidity | Temperature and humidity sensor |

| Vibration acceleration | Accelerometer | Vehicle load | Dynamic weighing system |

| Deformation displacement | GNSS, box-type fixed inclinometer | Bridge Deck Video | Infrared network high-speed ball machine |

| Settlement/deflection | Static level | Wind speed | Wind speed and directional meter |

| crack | Crack meter | earthquake | Accelerometer |

6.Bridge monitoring basis

"Technical Standard for Municipal Bridge Structure Monitoring DB22∕T 5035-2020"

"Bridge Structure Health Monitoring System Design Specification DB32∕T 3562-2019"

"Technical Regulations for Bridge Structure Monitoring System DG/TJ 08-2194-2016"

"Technical Regulations for Safety Monitoring System of Highway Bridge Structures JT/T 1037-2016"

"Technical Specifications for Monitoring of Building and Bridge Structures GB50982-2014"

"Structural Health Monitoring System Design Standard CECS-333-2012"

7.Bridge monitoring implements functions

1.Full life cycle monitoring: realize the full life cycle monitoring of the bridge, including related contents during the construction period and operation period, such as strain, temperature, linearity during the construction period, strain, linearity, vibration, environment, and stress during the operation period, perform data storage analysis, comprehensive display of GIS+BIM or GIS+4D models, master the entire life cycle status of the bridge, and provide a decision-making basis for management;

2.Automatic report push: In addition to real-time display of monitoring results, the system will automatically generate corresponding daily reports, and one-click download is supported.Once the data exceeds the threshold, timely warnings and notify relevant units to take corresponding measures in a timely manner;

3.Leveled early warning: Set different early warning levels according to requirements.When the data is abnormal, the early warning information will be automatically triggered according to the settings, including platform push, text messages and email notification to the corresponding person;

4.Accumulate bridge status data: provide necessary decision-making basis for long-term operation, maintenance, and reinforcement of bridges, and provide basis for the assessment of the safety status of bridges after emergencies.At the same time, AI algorithm is used to predict the structural response and development of the bridges in the future time period;

5.Provide reference basis: verify the bridge design and construction theory and construction technology, so as to improve relevant design and construction technical regulations and ensure the safety of bridge use.

In the modern industrial field, the chemical industry has an extremely high demand for meteorological monitoring. The chemical production process is complex and involves many flammable, explosive, and corrosive chemical substances. For example, in a chemical industrial park, under different meteorol...

When traditional mechanical weather stations monitor wind speed and direction, they encounter a difficult problem. The wind speed sensor usually consists of wind cups and an axis, and the wind direction sensor relies on mechanical components such as a wind vane. When these mechanical components are...

Meteorology encompasses a wide range of elements, such as rain, ice, wind, frost, clouds, and temperature, among others. In the power system, "micro-meteorology" is different from what is described in meteorology. Power micro-meteorology refers to the meteorological conditions in a small s...

Wheat seedling conditions are usually classified into strong seedlings, robust seedlings (including first - class and second - class seedlings), and weak seedlings (third - class seedlings). For different seedling conditions, differential management measures need to be taken during key growth stages...