Tianqiong Sensor IOT Technology Co., Ltd

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

Model:FT-CEMS-B

Brand:tianqiong

1.Introduction to Online CEMS Gas Analyzer Project

Online CEMS Gas Analyzer is an integrated system for measuring the concentration of flow, dust, air pollutants, mainly measuring the concentration of gases such as SO2, NO and O2.Online CEMS Gas Analyzer launched by Fengtu Technology can continuously monitor SO2, NOX, 02 (standard, wet-based, dry-based and converted), particulate matter concentration, flue gas temperature, pressure, flow rate and other related parameters, and count emission rates, total emissions, etc.Therefore, the measured data is effectively managed.

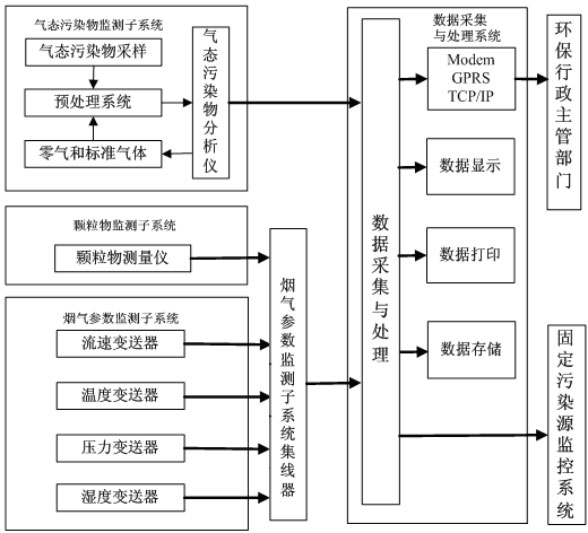

Online CEMS Gas Analyzer consists of four necessary subsystems: gaseous pollutants (SO2, NOX, 02, etc.), particulate matter monitoring, flue gas parameters (temperature, pressure, flow rate, etc.), and data acquisition and processing.

The monitoring of gaseous pollutants is pretreated by extraction condensation method + phosphoric acid titration method.The principle is to measure the SO2 and NOX content in the flue gas by ultraviolet differential method, measure the wet oxygen content through electrochemical method, and then calculate the dry flue gas concentration of SO2, NOX, and 02 through dry and wet conversion.The phosphoric acid titration pretreatment can effectively reduce the adsorption loss of SO2 during condensation and water removal, and improve measurement accuracy.

Particle matter monitoring is performed using a extraction measurement method, the temperature of the flue gas is measured by a temperature sensor, the pressure of the flue gas is measured by a pressure sensor, and the flue gas flow rate is measured by a pitot tube; all measurement signals are sent to the data acquisition and processing system.

The output processing system has functions such as real-time on-site data transmission, remote fault diagnosis, report statistics and graphical data analysis, which realizes unattended work site.The entire system has a simple structure, wide dynamic range, strong real-time performance, flexible networking and low operating costs.At the same time, the system adopts a modular structure, which is convenient for combination, and can fully meet the requirements of communication with the internal DCS system and the data system of the environmental protection department.

000011 Project Implementation Standard

The design, manufacturing and acceptance specifications of this system are mainly carried out in accordance with the following standards and technical specifications:

u GB3095-1996 "Atmospheric Environmental Quality Standards"

u GB13223-2003 "Standards for Atmospheric Pollutants Emissions in Thermal Power Plants"

u GB18485-2007 "Standards for Control of Pollutants for Incineration of Domestic Waste"

u HJ/T75-2007 "Technical Specifications for Continuous Monitoring of Flue Gas Emissions in Thermal Power Plants"

u CJJ90—2002 "Technical Specifications for Urban Domestic Waste Incineration Engineering"

u CJ/T118—2002 "Technical Specifications for Urban Domestic Waste Incinerators"

u HJ/T76-2007 "Technical requirements and detection methods for continuous monitoring system for flue gas emissions from fixed pollution sources"

u GB16297-1996 "Comprehensive Emission Standard for Air Pollutants"

u GB/T16157-1996 "Determination of Particulate Materials in Exhaust Gas from Solid Pollutants and Sampling Methods of Gas Pollutants"

u GB9078-1996 "Comprehensive Emission Standard for Air Pollutants in Industrial Furnace Kilns"

u GB 3095-1996 "Ambient Air Quality Standards"

u GB12519-1990 "General Technical Conditions of Analytical Instruments"

000012 Project Plan

000012.1 Measurement item

ØSO2, NOX, O2, smoke, temperature, pressure, flow rate

000012.2 Measurement method

ØFlue gas sampling method: extraction condensation method

ØSO2 and NOX monitoring methods: differential optical absorption spectroscopy (phosphate titration pretreatment)

ØO2 monitoring method: electrochemical method

ØSmoke measurement method: extraction measurement method

ØTemperature measurement method: temperature sensor

ØPressure measurement method: pressure sensor

ØFlow velocity measurement method: differential pressure method (pito tube)

2.Online CEMS Gas Analyzer system general rules

The technical requirements for functional design, structure, performance, installation and testing of this system equipment all meet the relevant national environmental protection standards and meet the standards requirements of the Environmental Protection Industry of the People's Republic of China (HJ/T75-2007, HJ/T76-2007).

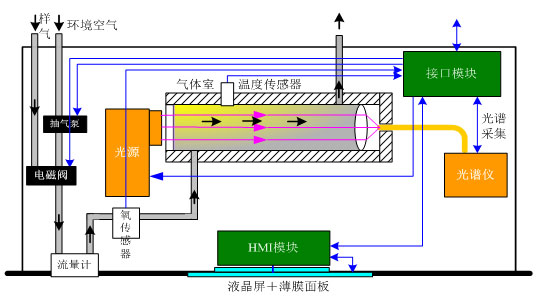

Our company's CEMS system consists of a gaseous pollutant monitoring subsystem, a particulate matter monitoring subsystem, a flue gas parameter monitoring subsystem and a data acquisition and processing subsystem.The gaseous pollutant monitoring subsystem and a data acquisition and processing subsystem are installed in a standard 19-inch cabinet.The system composition is as follows:

Figure 1, CEMS system composition diagram

ØGasy pollutant monitoring subsystem: consists of sampling unit, pretreatment unit and analysis unit.

Ø Particle monitoring subsystem: adopts a extraction smoke monitor.

ØFlue gas parameter monitoring subsystem: Pito tube is used to measure flow velocity, pressure sensor is used to measure pressure, temperature sensor is used to measure temperature, and flue gas humidity is measured by high-temperature capacitance humidity sensor.

ØData acquisition and processing subsystem: consists of data collector, industrial control machine, display and system software.

The above subsystems are cropped according to customer needs.

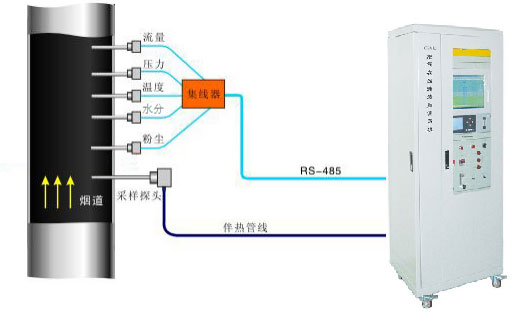

Figure 2.CEMS system installation diagram

3.System composition

3.1 Monitoring of gaseous pollutants

3.1.1 Sampling and Preprocessing Unit

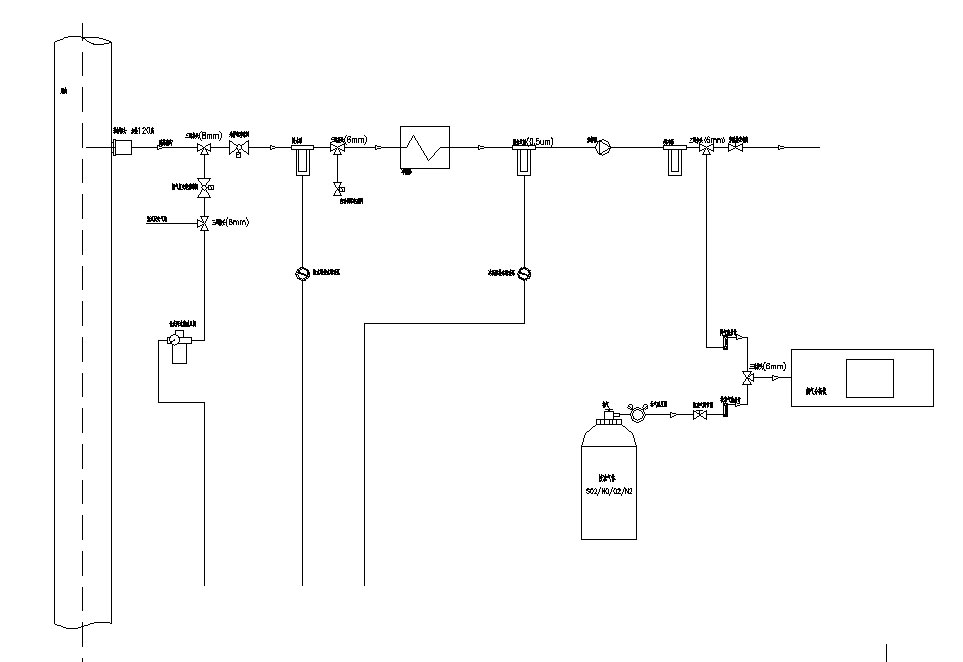

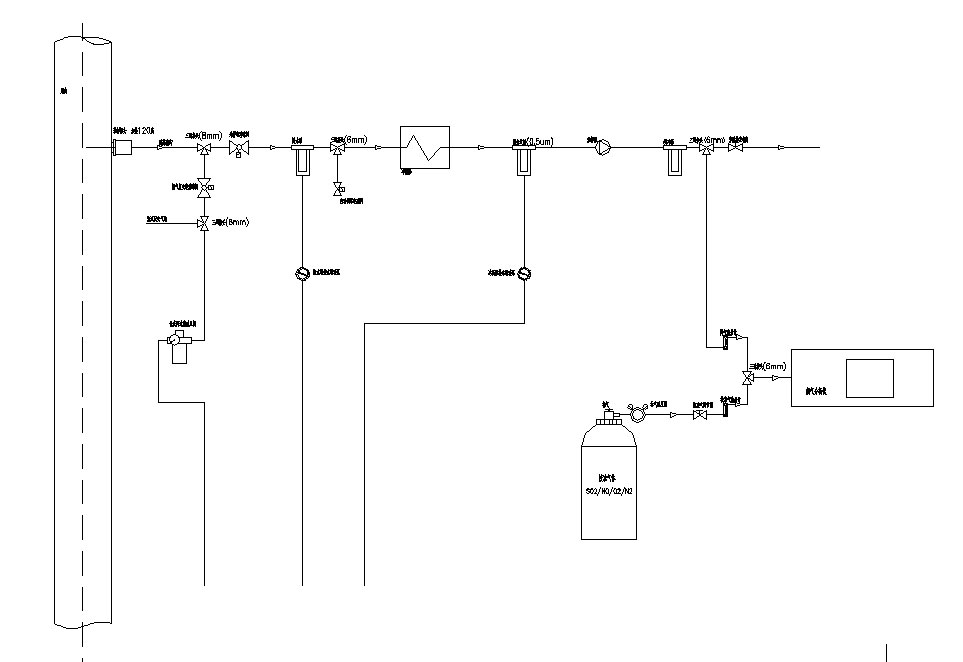

The sample gas is taken out by the sampling probe under the suction force of the sampling pump.Most of the particulate matter in the sample gas is filtered off by the filter in the sampling probe.After filtering, it is transported to the refrigeration system by the heating pipeline to condense and remove water, and sent to the analysis unit for analysis.According to the common characteristics of high humidity and small SO2 in ultra-low systems, in order to reduce the adsorption loss of SO2, the pretreatment system adopts a relatively reliable and simple phosphoric acid titration method, and adds more than 5% phosphoric acid solution to the condenser pretreatment, so that the condensed water is always in an acidic state, reducing the adsorption loss of SO2 and improving measurement accuracy.The condensed water is discharged through the drainage system.The control unit realizes functions such as backblowing, calibration, and refrigeration temperature alarm prompts, and displays various working statuses of the system.

The first-stage rapid condensation is used in the pretreatment system to ensure that the gas components remain unchanged.Secondary fine filtration is adopted to ensure that the gas measuring chamber is not contaminated, thereby improving the service life of the analyzer.The following figure is the flow chart of the gaseous pollutant monitoring system.

3.1.2 Gas analyzer

Instrument: UV spectrum gas analyzer

Model: HM-UVA-100

Measurement principle: Differential optical absorption spectroscopy (DOAS)

Measurement principle

UV spectroscopy gas analyzer is a gas analysis instrument based on multi-channel spectroscopy analysis technology (OMA) and differential optical absorption spectroscopy technology (DOAS).The beam emitted by the light source converges into the optical fiber and is transmitted to the gas chamber through the optical fiber.When passing through the gas chamber, it is absorbed by the gas to be measured and transmitted to the spectrometer.After being spectroscopic through gratings inside the spectrometer, the spectroscopic signal is converted into an electrical signal by the array sensor to obtain the continuous absorption spectral information of the gas.Based on this spectral information, the instrument uses differential absorption spectroscopy algorithm (DOAS) and partial least squares algorithm (PLS) to obtain the concentration of the measured gas.

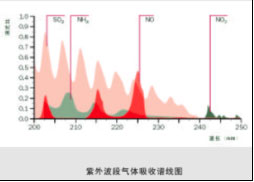

ØMulti-band spectroscopy analysis technology (OMA)

Since various gas molecules have different absorption of light waves in different bands, the simultaneous measurement of multiple gases is achieved through the analysis of the continuous spectrum after gas absorption.

The UV spectroscopy gas analyzer uses ultraviolet band light sources and sensors to measure the concentration of gases absorbed by light waves in the ultraviolet band, such as SO2, NO, NO2 and other gases.

ØDifferent optical absorption spectroscopy (DOAS)

The core idea of DOAS is to decompose the absorption spectrum of the gas into two parts: fast change and slow change.The fast-changing part is related to the structure of the gas molecules and the elements it consists of, and is a characteristic part of the absorption spectrum of the gas molecules; the slow-changing part is related to the interference of smoke, water vapor, background gas, and changes in the measurement system, and is an interference part.DOAS uses the fast-changing part to calculate the concentration of the measured gas, and the measurement results are not disturbed and have high accuracy.

The UV spectroscopy gas analyzer adopts a unique DOAS algorithm and PLS algorithm to eliminate interference from smoke, water vapor and background gas, and also eliminate the impact of measurement system fluctuations on measurement results, ensuring the accuracy and stability of measurement.

Technical Indicators

SO2: 0~20~100ppm (can be customized according to the buyer's needs)

NO: 0~20~100ppm (can be customized according to the buyer's needs)

Accuracy: ≤±2%

Linear error: ≤±2%FS

Zero point drift: ≤±2%FS/7D

Range drift: ≤±2%FS/7D

Response time: ≤30s

other

O2 measurement electrochemistry, 0~25%, ≤±2%FS

Power supply: 220VAC, 50Hz

Ambient temperature limit: -10~40℃

Communication interface: 1 channel RS232; 1 channel RS485/RS232

Digital interface: 4 relay output, 2 binary input

Analog interface: 5 channels 4~20mA output, 2 channels 4~20mA input

Instrument features

ØHigh reliability

It uses pulse xenon lamp with a lifespan of up to 10 years as the light source, and uses a curing spectrometer, with no moving parts and high reliability.

ØCombined gas chamber design

The combined gas chamber design makes spectral adjustment simple and improves spectral intensity.

ØHigh measurement accuracy and good stability

The DOAS (differential optical absorption spectrum) algorithm is used, and the measurement results are not disturbed by factors such as smoke and moisture, and have high measurement accuracy; at the same time, the DOAS algorithm also eliminates errors caused by instrument aging and has good measurement stability.

ØHighly intelligent and digital

It has built-in multiple high-performance processors, and the processors use high-speed data bus communication technology.Each module has powerful digital configuration and detection functions; it is simple to operate and easy to use.

Ø Rich user interface

Provides rich interfaces that can be easily integrated into various control and monitoring systems.Wireless or wired networks can be formed through communication methods such as RS485 and RS232 to facilitate the daily operation, maintenance and management of the instrument.

ØComparison with common analyzers

category | HM-UVA-100 | Non-spectroscopic infrared (NDIR) |

Spectral range | Holographic grating spectroscopy, diode array detector, complete continuous absorption spectrum | Non-spectroscopic, bandpass filter, measurement of absorption at characteristic wavelengths |

Wavelength resolution | High, 0.6nm | Low, 20-30nm |

Linear response | High wavelength resolution ensures linear response | Large filter passband width results in nonlinear response to gas concentration |

Measure dynamic range | Large, suitable for simultaneous measurement before and after desulfurization | Small |

Effects of flue humidity | Not affected by smoke humidity | Humidity and filter devices affect calibration results |

Calibration cycle | Wide continuous spectrum, high wavelength resolution, long calibration period | Short calibration period |

Anti-interference capability | Very strong, wide continuous spectrum and high wavelength resolution eliminate interference from particulate matter, moisture, and background gases | Weak, especially easy to be disturbed by moisture |

reliability | No moving parts inside, good reliability | There are moving parts such as choppers, which affect operating reliability |

Online CEMS Gas Analyzer3.1.3 Analysis System

The analysis system is composed of:

ØSampling unit (probe, filter, thermostat);

The sampling unit of the FT-CEMS-B system is mainly composed of a sampling probe and a heat tracing pipeline.Install the sampling probe in the appropriate position of the flue (or chimney) in accordance with national specifications, collect gas in the flue, and transport the gas to the heating box located inside the cabinet through a heat tracing pipe.To ensure the accuracy of the measurement results, the sampling probe and the heating pipeline are both electrically heat-tracing, which can keep the gas at a set temperature to prevent moisture from condensing in the gas.The length of the heating pipeline can be customized according to the actual needs of the buyer.

Ø Pretreatment unit (sampling pump, dehumidification, fine filtration, drainage, etc.);

The flue gas reaches the pretreatment system through the high-temperature sampling probe and heat tracing pipe.The pretreatment system enters the condenser through the sampling ball valve for steam separation.The condensed water is discharged in time through the peristaltic pump.The condensed water is dehydrated through the condenser, and dust filtered through the third-level fine filter.The treated clean dust-free sample gas enters the flue gas analyzer for analysis and measurement.

ØAnalysis unit (SO2, NO, NO2, O2);

ØSignal output (SO2, NO, NO2, O2 concentration, range conversion, calibration state, fault state, etc.);

ØOthers (gas circuits, circuits, etc.);

ØAnalytical instrument cabinet: 1800×530×730MM (height*deep*width).

3.2 Particle monitoring

Instrument: Extract smoke (powder) dust measuring instrument

Model: LFS1000-MO

Measurement principle: laser extraction

Technical parameter table:

How it works | Principles of laser forward scattering measurement |

Determination object | Industrial waste gas, smoke and dust |

Mechanical characteristics | Mainframe housing: All metal housing |

Host size: 1670×750×600 mm (H×W×D) | |

Weight: about 120Kg | |

Protection level: system IP55, electronic components IP65 | |

Optical properties | Operating wavelength (650±20) nm |

Measure performance | Measuring range: automatic switching between dual ranges, minimum (0-5) mg/m3 maximum (0-200) mg/m3 |

Zero point drift: ±2%FS/24h Range drift: ±2%FS/24h | |

Display error: ±2%FS | |

Detection limit: 0.01mg/m³ Flue diameter: (0.3~20) meters | |

Measurement conditions | Flue flow rate: (0~30) m/s; Flue pressure: -5Kpa ~5Kpa Flue gas temperature: maximum 300℃ Flue gas humidity: 30mg/m3 Anti-blocking and backblowing: Automatic, backblowing time interval can be set |

Host power supply requirements | Voltage 220VAC, power 3KW |

Working environment | Working temperature: -20℃~+50℃ |

Interface features | Analog output: (4~20)mA |

Digital interface: RS485 |

Implementation standard: HJ/T 76-2007 Technical requirements and detection methods for continuous monitoring system for flue gas emissions from fixed pollution sources.

Product performance features:

It adopts a homogeneous probe for speed measurement and sampling to support accurate isometric sampling.

Supports four parameters to output simultaneously: flue temperature, flue pressure, flue flow rate, and flue concentration.

The instrument adopts a variety of advanced technologies.Including: related noise cancellation technology, laser emission power stability technology, extremely low noise TIA, interference control and signal integrity design, and anti-hard environment design technology, providing fast, reliable and accurate quantitative smoke emission data.

Unique automatic calibration patented technology to achieve automatic calibration of zero point and full scale.The system automatically performs zero-point calibration and full-scale calibration every 24 hours.It also supports manual zero point calibration and automatic zero point calibration.

The jet technology is used to extract part of the flue gas from the flue.It has a compact structure, simple installation, lightning resistance, harsh environment resistance, low cost and small maintenance.

The flue gas sampling and transmission process are continuously heated and constant temperature to prevent measurement errors caused by the condensation of wet flue gas during the transmission process.

It adopts intelligent technology and has display functions, which can display various test data and fault prompts in real time, making it convenient for on-site debugging and maintenance.

Exclusive equipment operating status prompts, temperature abnormalities, and parameter abnormalities.

The power-off self-protection function is used to power it with a backup battery after power off, close the valve and protect the internal structure.

3.3 Flue gas parameter monitoring

3.3.1 Temperature and pressure flow integrated probe (temperature, pressure, flow rate)

The structure of the temperature-pressure-flow integrated probe measuring device mainly includes micro-differential pressure transmitter, static pressure sensor, thermal resistance (or thermocouple), pitot tube, back-blowing solenoid valve, temperature and pressure compensation, etc.The measurement principle is: the primary pressure-taking element adopts the traditional pitot tube measurement method.After correct installation, the full pressure and back pressure pressure picking tube of the pitot tube transmit the detected dynamic pressure and static pressure to the differential pressure transmitter respectively.The differential pressure transmitter converts the difference between the dynamic pressure and static pressure into 4~20mA square proportional current to transmit to the distribution box data acquisition module, and the computer in the CEMS cabinet performs data processing.

The inner and outer surfaces of the pitot tube have been specially treated to effectively avoid flue gas corrosion and reduce dust adhesion.The back-blowing solenoid valve is mainly used for system back-blowing when measuring dirty gases (such as flue gas discharged from the boiler): When the probe detection hole adheres to and accumulates dust and dirt, the solenoid valve is opened regularly or according to the predetermined procedure, and the compressed air is connected to two pressure-taking pipes at the same time for blow-off operation.During normal measurement, the solenoid valve is in a closed state.

Technical Features

l Can measure the temperature, pressure and flow rate of the flue gas in real time, and output 4~20mA through 3 analog signals two-wire system.

l Automatically and regularly blow back the dynamic and static pressure ends of the Pito tube.

lHigh measurement accuracy, good reliability, and can work continuously for a long time.

lEasy installation and wiring, and low maintenance.

Technical Indicators

ØSpan: Linear output 0-30m/s;

ØOutput signal: 4~20mA two-wire system;

ØMeasurement accuracy: ±2%FS;

ØCheck frequency: 12 months;

ØResponse time: <1s;

Ø Differential pressure (temperature, pressure) transmitter power supply: 24VDC, two-wire system;

ØDifferential pressure transmitter overvoltage limit: 4.0MPa;

ØPitto tube material: 304, 316L stainless steel;

ØNormal closed back-blowing solenoid valve power supply: 220VAC, 50Hz;

ØPitto tube insertion length: 500~2000mm optional;

ØPressure transmitter range: -5~+5kPa;

ØTemperature transmitter range: 0~300℃;

ØMedia temperature range: -40~500℃;

ØAmbient temperature: -40~85℃;

ØStorage temperature: 0~50℃;

ØStorage humidity: 0~85%RH.

ØInstallation flange: DN50;

ØMaterial: SUS316L

The difference between conventional CEMS and ultra-low CEMS

Parameters and scope of conventional CEMS flue gas online monitoring system

parameter | Measurement range | method |

SO2 concentration | (0-700) mg/m³ (range can be expanded) | UV differential method |

NO concentration | (0-350) mg/m³ (range can be expanded) | UV differential method |

Flue gas flow rate | (0-40) m/s | S-type pitot tube differential pressure method |

Oxygen content | (0-25)%vol | Electrochemical method |

Flue gas temperature | (0-400)℃ | PT100 |

Flue gas pressure | (-1000~1000) Pa | Pressure transmitter |

Particulate matter | (0-200) mg/m³ | Laser post-scattering |

humidity | (0-40)% | Resistive capacitance |

Ultra low cems + ultra low dust (this model is designed for areas with strict environmental protection requirements, and smoke and dust are independent structures)

Ultra-low CEM flue gas emission continuous monitoring system

Monitoring parameters and range

parameter | Parameter range | parameter | Parameter range |

Measurement principle | UV differential spectroscopy | Repeatability | ≤0.5% |

Measurement items | SO2, NO, O2 (electrochemical principle) | Warm-up time | 60min |

Range | SO2(0-200)mg/m³ NO(0-130)mg/m³ O2(0-25)mg/m³ | Flow rate | (5-40) m/s |

Linear Error | No more than ±1%FS | temperature | (0-400)℃ |

Zero point drift | No more than ±1%FS | pressure | (±10) Pa |

Range drift | No more than ±1%FS | Voltage impact | The analyzer reading changes shall not exceed ±2%FS |

Sample air flow | 1-1.5L/min | Communication interface | RS232, RS485 (supports Modbus protocol) |

Ultra-low emission dust monitoring system

Parameters and ranges

parameter | Parameter range | parameter | Parameter range |

How it works | Principles of laser forward scattering measurement | Detection limit | When the full scale value of the analytical instrument is ≤50mg/m³, the detection limit is ≤1.0mg/m³ (the full scale value is >50mg/m³, no requirements are made) |

Measurement items | Industrial waste gas, smoke and dust | ||

Optical features | Operating wavelength (650±20) nm | Measurement conditions | Flue flow rate: (0-30) m/s |

Power supply requirements | AC380V or 220V is optional, with a power of 3KW | Flue gas temperature: maximum 300℃ | |

Range | 0-20mg/m³ Other ranges can be customized | Working environment | Working temperature: -20-+50℃ |

Zero point drift | No more than ±1%FS | Interface features | Analog output (4-20) mA Digital interface: RS485 |

Range drift | No more than ±1%FS | Flow rate | (5-40) m/s range can be customized |

pressure | (±10) Pa range can be customized | temperature | (0-400) ℃ range can be customized |

the difference:

1.The specific measurement range of the equipment analyzer is different.

2.The equipment measurement parameters are different.For example, ordinary measured particulate matter is post-scattered by in situ laser, and ultra-low measured particulate matter is pre-scattered by extraction laser.

3.Different analyzer gas chambers are used, single gas chambers of ordinary analyzers and double gas chambers of ultra-low analyzers, with small ranges, long optical paths, and higher accuracy.Ultra-low analysis adds unique prisms.Regularly not.Make it more accurate.

When choosing ordinary equipment and ultra-low equipment, you must choose correctly according to local policy requirements.

The petrochemical production process involves a large number of flammable and explosive chemical substances, such as crude oil, gasoline, ethylene, and so on. During storage, transportation, and production, these substances can easily trigger explosions and fires once they encounter an ignition sour...

The Portable el detector is an important device used to detect various defects in photovoltaic (PV) cell modules. It can accurately detect defects such as hidden cracks, fragments, and poor soldering in PV cell modules. These internal defects can seriously affect the service life and long-term power...

With the booming development of ecotourism, scenic weather stations have become common devices in major tourist attractions and ecological parks (such as artificial wetlands, ecological parks, botanical gardens, etc.). It is dedicated to the all - day automatic online collection of air cleanliness i...

In the fields of solar energy resource assessment and meteorological monitoring, the Fully Automatic Solar Spectrometer is revolutionizing traditional measurement methods. This instrument combines multi - spectral filters with thermopiles to capture radiant energy within the spectral range of 280 to...